What is filtration Friends, water is a basic need of man without water man cannot live water is an integral part of our life so tell me what process the tap water in your house has gone through before it reaches you through this post you can know how filtration on water treatment plant What you are going to learn is done, you can use it for your environmental engineering exam.

What is filtration/theory of filtration?

the process in which solid particles in a liquid or gaseous fluid are removed by the use of a filter medium that permits the fluid to pass through but retains the solid particles.

Types of Filtration

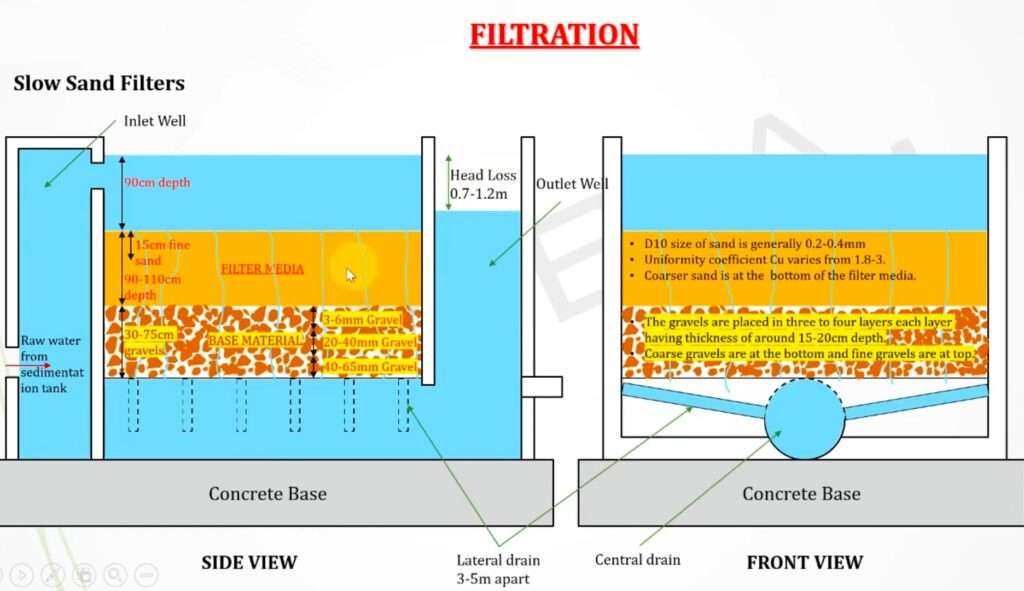

1) Slow sand filter

2) Rapids and filter

Slow Sand Filtration Process

Rate of Filtration

The rate of filtration is generally about 100-200 liters per hour per sq.m. of filter area.

The area of slow sand filters can vary from 100-2000 square meters.

Efficiency

Slow sand filters are highly efficient in removing bacteria and other suspended solids from raw water.

Bacteria removal is 98-99%.

The filter also removes odor and taste due to the presence of organic impurities.

Cannot remove color.

Slow Sand Filtration Process

The slow sand filtration process is a method used to clean water by passing it through a bed of sand at a slow rate. It works by removing impurities and particles from the water as it passes through the sand.

Here’s a simplified explanation of the process:

Water collection: Dirty water is collected from a source, such as a river or well.

Pretreatment: Large debris and particles are removed from the water to prevent clogging of the sand bed.

Sand bed: The water is then passed through a bed of fine sand. The sand acts as a natural filter, trapping and removing impurities from the water.

Filtration rate: The water is passed through the sand at a slow rate, allowing enough contact time for the sand and the biological layer to effectively filter out impurities.

The slow sand filtration process is an affordable and sustainable water treatment method, commonly used in small-scale and community water systems. It provides an efficient way to remove particles, pathogens, and other contaminants from water, making it safe for drinking and other uses.

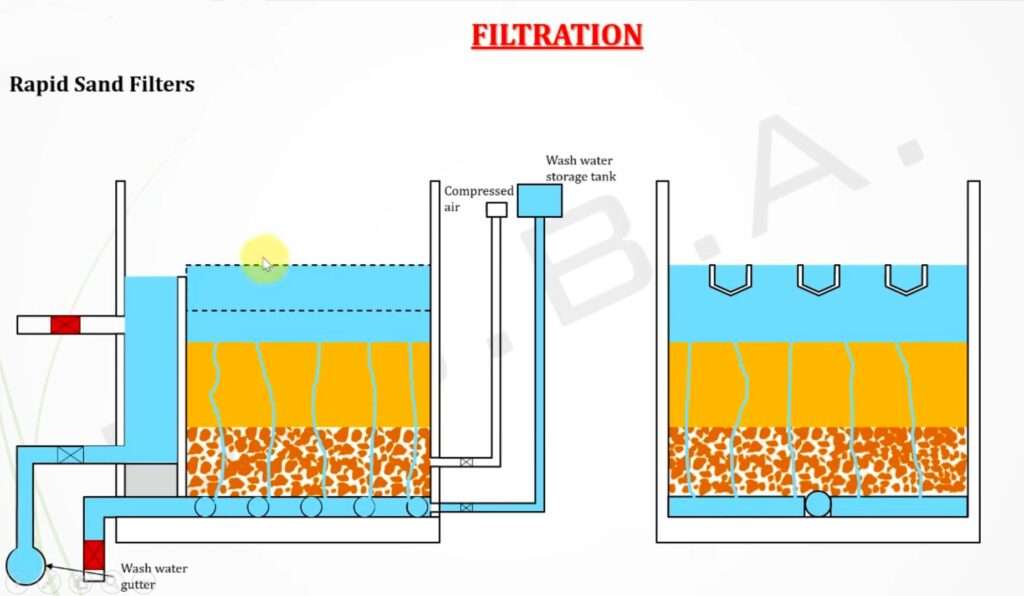

Rapid Sand Filters

Base Material

Base material as in the case of the slow sand filter here also is made of gravel.

In addition, to supporting the sand on top of it, in rapid sand filters the gravels play a very important role in distributing the backwash water in the sand.

The thickness is generally 60-90cm.

The gravels are placed in 4-5 layers each layer of 10-15cm in depth.

The coarsest gravels are placed at the bottom.

Bottom gravels size: 20-40mm; Intermediate gravel size: 12-20mm; top gravel size: 6-12mm.

Filter Material

The filtering media consists of sand layers, about 60-90 cm in depth. • The effective size D10 of the sand varies from 0.35 to 0.55

The coefficient of uniformity Cu is between 1.3 to 1.7.

Sand is laid in layers where the topmost layers are of fine sand and the bottom is coarse sand.

Under drainage system:

In a slow sand filter, the under drainage system was provided only to receive and deliver the filtered water.

In rapid gravity filters, the under drainage system is provided to receive and deliver filtered water as well as to allow back washing of the filter.

It consists of a Manifold & lateral system: In this, a central pipe called a manifold about 40cm diameter runs length-wise, on both sides of the manifold 10cm diameter laterals are connected to it at a spacing of around 15-30cm apart.

Design of Under Drainage

The total area of perforations = 0.2% of total filter area.

Cross-sectional area of lateral = 2-4 times the area of perforations.

Cross-sectional area of manifold = 2 times the area of laterals.

Length of each lateral > 60

Dia of lateral

Rapid Sand Filters

Backwashing

Backwashing consists of passing filtered water upwards through the bed at such a velocity that causes the sand bed to expand to about 25-40% of its volume.

Due to this the grains move and rub against each other thus cleaning themselves.

Backwashing is usually done when the head loss measured of filtered water reached 2-3m indicating that the sand has become dirty causing more frictional losses.

The back washing is done at a high rate of about 300-900 liters/min/sqm (6 to 18 times the filtration rate) for about 15 minutes

The backwashing rate is determined on the basis that backwashing velocity should not exceed the settling velocity of the finest sand particle (generally 0.3-0.9 m/min), otherwise backwashing may deplete the filter media of fine particles.

The amount of water required for backwashing maybe 2-5 % of total filtered water.

Air compressor

During backwashing the sand grains are agitated by a jet of water or compressed air.

Operational troubles: Mudballs

If frequent backwashing of the filter is not done then the mud from the atmosphere settles on the top layer of the sand forming a mud layer.

This layer settles into the sand and gravels forming nud balls and also interfering with the back washing process.

Once mud balls are formed, if not cleaned in time they go on accumulating till they fill the entire space.

The following methods are used to remove mud balls:

- Mud balls can be broken using some mechanical rakers.

- Mud balls can also be broken using water steam, and then the mud balls can be removed using water under pressure.

3. The bed of the filter is first washed, then water is removed from the first 10cm depth above the bed and then caustic soda is applied. After 12 hours of soaking, the sand is thoroughly agitated and then washed.

Filtration rate and efficiency

- The rate of filtration that can be obtained is 50-100 liters/min/sq. meter of the plan area.

- The area of each unit is generally 10-80 sq. metres.

Rapid gravity filters as compared to slow sand filters are less efficient in removing turbidities and bacteria.

They can remove 80-90% of bacteria and 35-40 mg/L of turbidity.

The remaining is treated in a disinfection unit.

NUMBER OF UNITS REQUIRED FOR FILTRATION

N = 1.22√Q

Where,

N = Number of filter units.

Q = Plant capacity in a million liters per day.

For a plant of more than 9 million litres per day, no single unit should have a capacity greater than 1/4th of the capacity of that plant.

Important Links

AIR POLLUTION – DEFINITION | EFFECT | CONTROLLING

TYPE OF WATER INTAKE STRUCTURES | WORKING | NOTES

List of URLs with Alt Text

- Project Management in Civil Engineering

- Project Life Cycle Guide

- Construction Quotation Template

- Epoxy Flooring Paint

- Best Measuring Tapes Collection

- Construction Insurance Companies

- Landfill and Solid Waste Management

- SSC Junior Engineers Recruitment 2024

- Compound Wall Design Ideas

- Source of Water Types and Differences

- Town and Country Planning Notes

- Modern Road Barriers

- Modern Parapet Wall Design Ideas

- Single Floor House Design

- Anti-Termite Treatment Guide

- Free Building Estimation Excel Sheet

- E-Tender CPWD Guide

- Kitchen Tiles Design

- Campus Placement for Civil Engineering Students

- Water Cement Ratio Calculation

- PVC Ceiling Design Ideas

- Types of Glass in Construction

- DLC in Road Construction

- BRO – Border Roads Organization

- PWD – Public Works Department

- Construction Safety Equipment

- Exterior Door – Outswing Doors

- Structural Audit Stages

- Toilet Parts and Working

- Types of Admixtures in Concrete

Bamboo crash barrier used in National Highway Construction

15+ Trending Admixtures used in Construction

Highly Used Cement Type in National Highway Construction

Hi! I’m Sandip, a civil engineer who loves sharing about Civil Engineering & new ideas and tips. My blog helps you learn about engineering in a fun and easy way!

Wow, Really Good information about Filtration. This post very helpful for me.