Discover what shoring in construction is, its vital meaning, and the different types of shoring used to keep buildings safe. Learn why shoring is essential for excavation, repairs, and adjacent construction projects.

Table of Contents

Shoring in Construction: The Essential Guide to a Safer Build

Have you ever walked past a construction site and seen a complex network of metal beams and wooden planks holding up a wall or supporting a deep excavation? You were looking at a temporary, but absolutely critical, structural system known as shoring in construction. It’s the unsung hero of the building world, working behind the scenes to prevent collapses and ensure the safety of workers and the public.

But what exactly is it? Why is it so crucial? In this ultimate guide, we will demystify everything about shoring in construction. We’ll explore its core meaning, the various types used on sites every day, and the fundamental reasons it’s a non-negotiable part of modern building practices. Whether you’re a student, a budding engineer, or simply curious about how buildings stand tall (and stay standing during repairs), this article is for you.

What is Shoring in Construction? Let’s Start with the Basics

Let’s answer the most fundamental question first: what is shoring in building construction?

In simple terms, shoring in construction is the practice of using temporary supports to prop up a building, structure, or trench to prevent collapse. Think of it as a crutch for a building. When a structure is weakened due to renovations, adjacent excavation, or is simply not yet able to support itself, shoring in construction provides the necessary stability.

The meaning of shoring in construction goes beyond just “holding something up.” It’s a carefully engineered solution that transfers loads safely to the ground, ensuring that the existing structure, the new work, and the workers are all protected. The primary goal of any shoring in construction project is safety.

So, when we define shoring in construction, we are talking about a temporary structural assembly designed to provide lateral, vertical, or both types of support during construction, repair, or emergency situations.

The Who, What, When, Where, Why, and How of Shoring

To fully grasp the concept, let’s break it down using a simple journalistic framework.

What is Shoring?

As defined above, shoring in construction is a temporary support system. It’s distinct from “formwork” (which holds wet concrete) and “scaffolding” (which provides a platform for workers). Shoring is all about load-bearing and stabilization.

Why is Shoring Used? (The Critical Importance)

The reasons for using shoring in construction are numerous and vital:

- Safety: The number one reason. It prevents catastrophic structural failures and protects human lives.

- Stability: It provides stability to structures that are being altered, have become unstable, or are adjacent to new excavations.

- Enabling Construction: It allows for safe excavation, foundation work, and repairs that would otherwise be impossible.

- Legal and Regulatory Compliance: Adherence to building codes and safety regulations often mandates the use of proper shoring in construction.

Where is Shoring Commonly Used?

You will find shoring in construction being used in various scenarios:

- Deep Excavations: Supporting the sides of deep trenches for utilities or foundations.

- Adjacent Construction: When building a new structure right next to an existing one.

- Structural Repairs & Renovations: When removing or altering load-bearing walls or columns.

- Emergency Situations: To stabilize a structure after an event like an earthquake or impact that has compromised its integrity.

When is Shoring Installed and Removed?

Timing is crucial for shoring in construction. It is installed before any potentially destabilizing work begins. It remains in place until the structure has gained sufficient strength (like concrete curing) or the permanent structural elements are in place and can carry the full load. Premature removal is a leading cause of accidents.

Who is Responsible for Shoring?

The design and implementation of shoring in construction is a highly specialized task. It typically involves:

- Structural Engineers: They design the shoring system, calculating the loads and specifying the materials and methods.

- Contractors & Shoring Specialists: They are responsible for the correct installation, maintenance, and safe removal of the shoring system on site.

How is Shoring Installed?

The “how” depends on the type of shoring in construction being used. Generally, it involves a systematic process of surveying the site, installing vertical posts (soldiers), horizontal wales, and struts, all while continuously checking for alignment and stability. Proper installation is key to the effectiveness of shoring in construction.

Delving Deeper: The Core Meaning and Purpose of Shoring

To truly understand shoring in construction meaning, we must look at its fundamental purpose: load transfer and redistribution.

When you excavate next to an existing building, you remove the soil that was laterally supporting its foundation. This can cause the building to tilt or even collapse. Similarly, when you remove a load-bearing wall inside a house during a renovation, the load from the floor above needs a new path to the foundation.

Shoring in construction provides that new path. It acts as a bridge, safely channeling these loads away from the weakened area and into stable ground or other sound structural elements. The meaning of shoring in construction is, therefore, synonymous with safety through intelligent load management.

This process is fundamental to many construction projects. For large-scale projects, accurate planning is essential, and tools like a comprehensive Bar Bending Schedule (BBS): Step-by-Step Guide + Download BBS Excel Sheet Free are invaluable for managing the reinforcement details that will eventually replace temporary supports.

A Comprehensive Look at the Different Types of Shoring in Construction

There isn’t a one-size-fits-all solution. The method used depends entirely on the project’s specific needs. Let’s explore the main types of shoring in construction you’re likely to encounter.

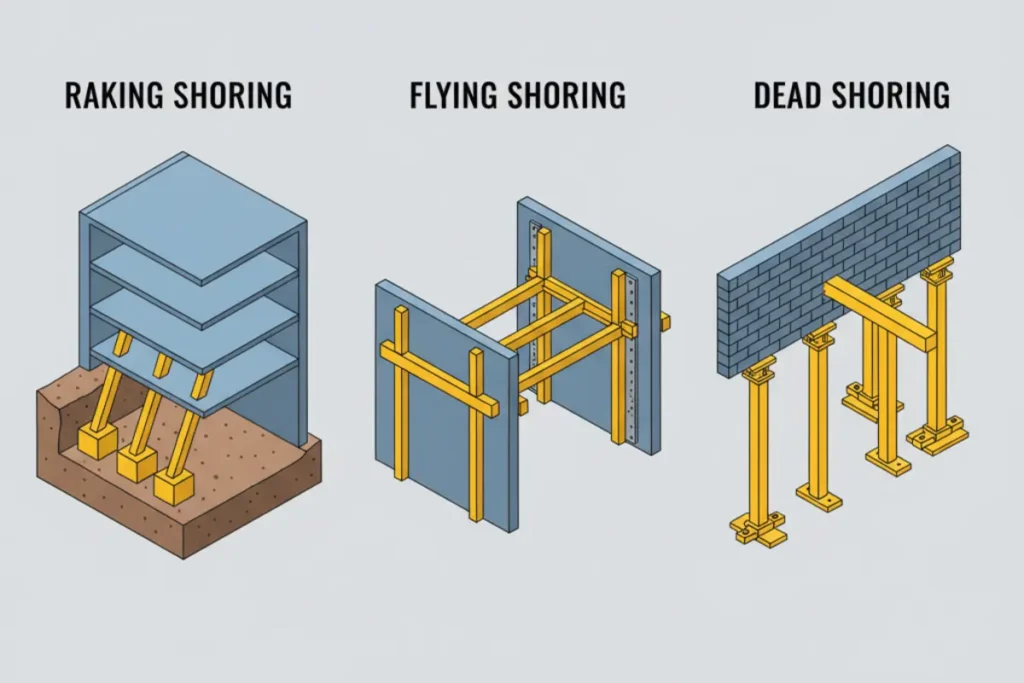

1. Raking Shoring

This is one of the most traditional and recognizable types of shoring in building construction. It involves installing inclined members, called rakers, that transfer the lateral thrust from an unstable wall to the ground at an angle.

- How it Works: The top of the raker is secured to the wall needing support, and the bottom rests on a sole plate on the ground. The horizontal thrust is converted into a more manageable vertical force at the base.

- Best For: Supporting the external walls of a building, typically when excavating close to it.

2. Flying Shoring (Horizontal Shoring)

This system provides horizontal support between two buildings, creating a “flying” or suspended effect. It’s a fantastic solution when two parallel structures need mutual support, and there’s no space for raking shores.

- How it Works: It consists of horizontal members (needles or flyers) that are wedged between the two walls. These horizontal members are supported by horizontal struts and cleats.

- Best For: Providing support to two adjacent structures where the intermediate building has been demolished or is being constructed.

3. Dead Shoring (Vertical Shoring)

Also known as vertical shoring, this system is used to support the vertical loads of a structure, such as when a load-bearing wall or a ground-floor column needs to be removed or replaced.

- How it Works: Vertical posts (called dead shores or uprights) are installed on either side of the wall to be removed. A horizontal beam (a needle) is then passed through the wall, which transfers the load from the structure above onto the vertical dead shores.

- Best For: Underpinning foundations, reconstructing ground-floor walls, or creating new openings in load-bearing walls.

The table below summarizes the primary shoring types in construction for quick reference:

| Type of Shoring | How it Works | Primary Function | Common Use Case |

|---|---|---|---|

| Raking Shoring | Uses inclined members (rakers) to transfer load to the ground. | Provides lateral support from the side. | Excavation next to an existing building. |

| Flying Shoring | Uses horizontal members strutted between two walls. | Provides horizontal support between two structures. | Supporting two parallel buildings during intermediate construction. |

| Dead Shoring | Uses vertical posts and horizontal needles to support loads from above. | Provides vertical support for loads from above. | Removing a load-bearing wall or column. |

Modern Shoring Systems in Construction

While the principles remain the same, modern technology has introduced more efficient and robust systems for shoring in construction.

Hydraulic Shoring

This is a life-saving system used primarily in trenching and excavation. It uses hydraulic pistons that can be easily and quickly expanded to press trench sheets or plates against the excavation walls.

- Advantages: Quick installation and removal, highly adjustable, and very safe as workers don’t need to be in the trench during installation.

- Best For: Trench works for pipelines, cables, and other utilities.

Pile Shoring (Secant and Contiguous Pile Walls)

This is a permanent or temporary retaining wall system used for very deep excavations.

- Secant Piles: Interlocking piles (reinforced concrete piles drilled through secondary, weaker concrete piles) that form a continuous, water-tight wall.

- Contiguous Piles: Piles drilled closely together but not interlocked, often used in dry soils.

- Best For: Deep basements in urban environments and sites with high water tables.

Sheet Piling

This involves driving interlocking sheets of steel, vinyl, or wood into the ground to create a continuous barrier that retains soil and water.

- Best For: Cofferdams, riverbank retention, and excavations in soft soil.

Choosing the right system from the various types of shoring in construction is a complex decision based on soil conditions, depth, water table, adjacent structures, and project budget. This is where sophisticated design software becomes critical. Engineers often rely on tools like ETABS Software Free Download for Windows 10 or STAAD Pro Software Free Download 2025 to model and analyze these temporary structures with precision.

The Critical Role of Shoring in Adjacent Construction and Excavation

One of the most high-stakes applications of shoring in construction is when building new structures right next to old ones. The risk of settlement, cracking, or even collapse of the adjacent building is very real.

In such scenarios, a comprehensive shoring plan is developed even before excavation begins. This plan, often part of a larger project managed with tools like a Row House Construction Estimation Excel Sheet, details how the existing foundation will be supported throughout the process. The shoring in construction here acts as a guardian, ensuring the old building remains perfectly stable while the new one rises beside it. This proactive approach is a key part of learning How to Save Up to $5000 in Construction by avoiding costly litigation and repair work due to negligence.

Shoring for Repair and Rehabilitation: Giving Buildings a Second Life

When a historic building needs restoration or a modern structure has suffered damage, shoring in construction is the first step. It allows engineers to safely dismantle, repair, or reinforce the damaged elements without worrying about a sudden failure.

The process involves a detailed assessment to identify all weakened areas, followed by the design and installation of a custom shoring system that provides targeted support. This meticulous planning is as crucial as the design phase itself, much like how detailed Almari Designs for Bedroom DWG File Download (Free + Modern Ideas) are needed before any fabrication can begin.

Best Practices for Safe and Effective Shoring

Implementing shoring in construction is not a matter of guesswork. It requires strict adherence to best practices:

- Professional Design: Always have the shoring system designed by a qualified structural engineer.

- Quality Materials: Use materials that meet the specified strength and quality standards. There are no shortcuts.

- Competent Installation: Installation should be carried out by experienced workers under expert supervision.

- Regular Inspection: Shoring must be inspected daily and after any event that could affect its integrity (e.g., heavy rain, seismic activity).

- Clear Communication: Everyone on site should be aware of the shoring plan and the associated risks.

Just as you would use specialized software like Revit Software for Civil Engineering Download for building design, using the right tools for planning, like a Download Free Building Estimation Excel Sheet, ensures that every aspect, including temporary works like shoring, is accounted for in the budget and timeline. For more complex calculations and project management, a tool like Microsoft Excel Free Download for PC: The Ultimate Tool for Estimation and Costing in Civil Engineering remains an industry staple.

Conclusion: Shoring – The Backbone of Construction Safety

From the deepest excavations to the most delicate structural repairs, shoring in construction is an indispensable practice. Understanding what shoring in building construction is, its various types of shoring in construction, and its fundamental meaning is crucial for anyone involved in the built environment.

It is a discipline that blends engineering principles with practical site knowledge to create safe working conditions and protect existing assets. The next time you see those metal beams and wooden planks on a site, you’ll appreciate the critical role they play. Shoring in construction is far more than just temporary timber and steel; it is the silent, strong backbone that allows progress to happen safely and efficiently.

Frequently Asked Questions (FAQs) About Shoring in Construction

Q1: What is the main difference between shoring and scaffolding?

A: Shoring is designed to support structures and heavy loads, providing stability to prevent collapse. Scaffolding is designed to provide a temporary working platform for workers and materials at height. Shoring is load-bearing; scaffolding is access-providing.

Q2: How long can shoring be left in place?

A: Shoring is a temporary system and should only be in place for the duration required by the construction activity. The timeline is specified in the shoring design. It must be removed once the permanent structure is capable of supporting all intended loads. Prolonged, unmaintained shoring can degrade and become a hazard.

Q3: Is shoring required for all excavation work?

A: No, not all excavations require shoring. The need is determined by the depth and soil conditions. Regulations (like OSHA) specify that excavations over a certain depth (typically 5 feet/1.5 meters) require protective systems, which can include shoring, sloping, or shielding.

Q4: Can shoring be reused on different projects?

A: Yes, many modern shoring systems, especially hydraulic shores and steel sheet piles, are designed to be reusable. They must be thoroughly inspected after each use to ensure they haven’t been damaged and still meet the required strength specifications.

Q5: Who is legally responsible for the shoring design and installation?

A: The ultimate responsibility for site safety, including shoring, typically falls on the general contractor. However, the shoring system must be designed by a licensed professional engineer (Structural or Geotechnical), and the installation is carried out by the contractor or a specialized shoring subcontractor.

External Articles for Further Reading:

- The Importance of Shoring in Construction Safety – Occupational Safety and Health Administration (OSHA) – A resource for official safety standards and regulations.

- Deep Excavation and Support Systems – The Constructor – A detailed technical article on modern shoring and earth retention systems.

Read More: Dive Deeper into Construction Insights

We hope this guide has given you a solid understanding of shoring in construction and its critical role in building safety. If you’re looking to expand your knowledge further, we have a wealth of resources that can help. Explore the articles below to master other essential aspects of civil engineering and construction:

- Bar Bending Schedule (BBS): Step-by-Step Guide + Download BBS Excel Sheet Free

Just as shoring provides temporary support, a proper BBS ensures the permanent strength of your concrete structures. Learn how to calculate and manage reinforcement steel efficiently. - How to Save Up to $5000 in Construction

Discover practical tips and strategies to reduce costs on your construction projects without compromising on safety or quality, from material selection to process optimization. - Row House Construction Estimation Excel Sheet

Proper planning is key to any successful project. Download our free Excel sheet to accurately estimate the materials and costs for building a row house. - Download Free Building Estimation Excel Sheet

Take your estimation skills to the next level with this comprehensive building estimation sheet, perfect for a wider range of construction projects. - Software Guides for Modern Engineers:

- STAAD Pro Software Free Download 2025 – Master this powerful structural analysis and design software.

- ETABS Software Free Download for Windows 10 – Specialized software for the analysis and design of building systems.

- Revit Software for Civil Engineering Download – Dive into Building Information Modeling (BIM) for smarter project management.

- Microsoft Excel Free Download for PC – Get the essential tool for every engineer’s costing and estimation needs.

- Best Almari Designs for Bedroom DWG File Download (Free + Modern Ideas)

For architects and designers, explore a collection of modern almari (wardrobe) designs with free DWG files to integrate into your next residential project.

Continue exploring CivilThings to find more free resources, guides, and downloads designed to empower students and professionals in the construction industry

Hi! I’m Sandip, a civil engineer who loves sharing about Civil Engineering & new ideas and tips. My blog helps you learn about engineering in a fun and easy way!