Table of Contents

Drywall Partition Guide: Types, Construction & Cost-Saving Tip Discover what a drywall partition is, its benefits, and how it’s built. Learn about different drywall sheets, fixing issues like bubbles, and get free construction tools.

Drywall Partition: The Ultimate Guide to Modern, Flexible Walls

If you’re planning an office renovation, dividing a large room in your home, or just curious about modern construction, you’ve likely heard the term “drywall partition.” But what is drywall, and why has it become the go-to choice for builders and designers worldwide?

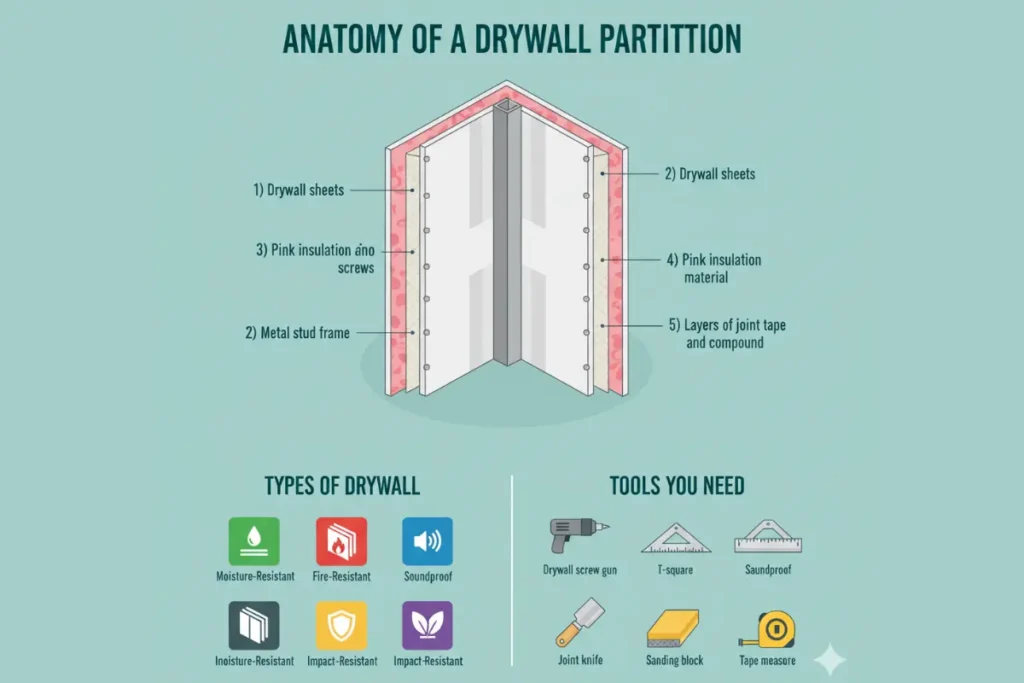

In simple terms, a drywall partition is an internal, non-load-bearing wall built using a framework of metal or wood and covered with drywall sheets. Unlike traditional brick-and-mortar walls, which use wet plaster, drywall construction is a “dry” process, making it incredibly fast, clean, and efficient.

This comprehensive guide will walk you through everything you need to know about drywall partitions. We’ll explore the drywall meaning, the different types of drywall, how they are built, and why they might be the perfect solution for your next project. We’ll also tackle common issues like drywall tape bubbles and drywall bulges, and even show you how this method can help you save money, much like the strategies in our guide on How to Save Up to $5000 in Construction.

What is a Drywall Partition? Understanding the Basics

Let’s start with the fundamental question: what is drywall?

Drywall, also commonly known as plasterboard, wallboard, or by the popular brand name Sheetrock, is a panel made of gypsum plaster squeezed between two thick sheets of paper. A drywall partition is a wall system created by attaching these panels to a frame.

The core component, gypsum, is a mineral known for its fire-resistant properties. This makes drywall construction not just fast but also safe. The process is called “dry” because it doesn’t require wet plaster that needs days or weeks to dry, significantly speeding up project timelines.

Why Choose a Drywall Partition? The Key Benefits

Why has this system become so popular? Here are the compelling reasons:

- Speed of Construction: A drywall partition can be erected in a fraction of the time it takes to build a masonry wall. There’s no waiting for mortar or plaster to dry.

- Cost-Effectiveness: It is generally more affordable than traditional methods due to lower labor and material costs.

- Design Flexibility: You can create curved walls, arches, and other complex designs easily with drywall.

- Smooth Finish: It provides a perfectly smooth surface ready for painting or wallpapering.

- Fire Resistance: Gypsum is inherently fire-resistant. Special fire-rated drywall offers even greater protection.

- Thermal and Acoustic Insulation: The cavity within the frame can be filled with insulation materials to keep rooms quiet and temperature-controlled.

- Ease of Repair: Damage like holes or dents can be patched up easily, unlike with brick walls.

The Building Blocks: Types of Drywall Sheets

Not all drywall is the same. The types of drywall available are designed to meet specific needs and challenges in different environments. Understanding these will help you choose the right one for your drywall partition.

Here’s a breakdown of the most common types of drywall:

| Type of Drywall | Core Features | Best Used For |

|---|---|---|

| Standard White | Standard gypsum core, white paper face. | Most interior walls and ceilings in dry areas. |

| Moisture-Resistant | Treated with additives and water-resistant green paper. | Bathrooms, kitchens, laundries. |

| Fire-Resistant | Contains glass fibers and other additives to enhance fire rating. | Garages, furnace rooms, party walls. |

| Soundproof (Acoustic) | Has a dense core or viscoelastic layer to dampen sound. | Home theaters, bedrooms, offices, media rooms. |

| Impact Resistant | Has a heavy, dense core and reinforced glass fibers. | High-traffic areas like hallways, schools, commercial spaces. |

| Mold-Resistant | Has a fiberglass face and mold-inhibiting agents. | Areas with high humidity or potential for water exposure. |

| Flexible | Thinner and more pliable for creating curved walls. | Arches, curved walls, and barrel ceilings. |

When planning your project, using a tool like our free Row House Construction Estimation Excel Sheet can help you calculate the quantity and cost of these different drywall types accurately.

Gypsum Partition Wall: The Science Behind the Strength

You’ll often hear the term gypsum partition wall used interchangeably with drywall partition. This is because the core material, gypsum, is what gives the panel its fundamental properties.

Gypsum (Calcium Sulfate Dihydrate) is a superb building material because:

- It is naturally fire-resistant, as it contains water in its crystalline structure. When exposed to fire, this water is released as steam, helping to slow the spread of flames.

- It can be easily mined, processed, and recycled.

- It provides a solid, durable surface that is still relatively lightweight.

So, when we talk about a gypsum partition wall, we are simply emphasizing the core material that makes modern drywall construction possible.

How is a Drywall Partition Built? A Step-by-Step Guide

The process of drywall construction is systematic. Here’s a look at how professionals build a drywall partition.

Step 1: Framing the Structure

The first step is to build the skeleton of the wall. This is typically done with metal studs or, less commonly, wooden studs. The studs are secured to the floor and ceiling tracks, creating a sturdy frame. The spacing of these studs is crucial for the stability of the drywall partition.

Step 2: Installing Drywall Sheets

The large drywall panels are then lifted and screwed onto the frame. This is where drywall screws come into play. These specialized screws have sharp points for easy penetration and fine threads that grip the metal or wood firmly without easily shaking loose. Using the correct drywall screws is critical to prevent future issues like a drywall bulge.

Step 3: Taping and Mudding

Once the sheets are up, the seams between them are visible. To create a seamless, smooth wall, a process called “taping and mudding” is used.

- Joint Compound (“Mud”): A special plaster-like material is applied over the seams.

- Drywall Tape: A perforated paper or fiberglass tape is embedded into the mud over the seams. This tape reinforces the joint and prevents it from cracking.

Step 4: Sanding and Finishing

After the mud dries, the entire surface is sanded smooth. Multiple coats of mud may be applied, with light sanding in between, to achieve a perfectly flat surface. This stage is dusty but essential for a professional finish.

Step 5: Adding Texture (Optional)

If a textured look is desired, a drywall ceiling texture or wall texture is applied using a roller, sprayer, or trowel. Popular drywall ceiling texture styles include “popcorn,” “orange peel,” and “knockdown.”

Step 6: Priming and Painting

Finally, the wall is primed and painted, transforming the drywall partition into a finished wall that blends seamlessly with the rest of the space.

For complex projects that involve structural elements, engineers often use software like STAAD Pro or ETABS for analysis, but for a non-load-bearing drywall partition, this is not necessary.

Common Drywall Issues and How to Fix Them

Even the best drywall construction can develop problems over time. Knowing how to identify and fix them is key.

1. Drywall Tape Bubbles

What it is: Drywall tape bubbles occur when the joint tape detaches from the wall, creating a visible bulge or bubble under the paint.

Causes: This is often due to improper application, such as insufficient joint compound underneath the tape or air bubbles being trapped during installation.

Fix: The affected area must be cut out, re-taped, and re-mudded with fresh joint compound.

2. Drywall Bulge

What it is: A drywall bulge is a larger, more pronounced swelling in the wall.

Causes: This can be more serious than tape bubbles. A drywall bulge is often caused by moisture damage from a leak, causing the gypsum core to swell. It can also be due to the drywall not being properly secured with enough drywall screws.

Fix: The source of the moisture must be fixed first. Then, the damaged section of drywall needs to be cut out and replaced.

3. Cracks

Causes: Minor cracks can appear due to the natural settling of a building. Larger cracks might indicate more significant structural movement.

Fix: Small cracks can be filled with joint compound and re-taped. For larger cracks, it’s best to consult a professional.

Drywall Drop Ceiling: A Versatile Ceiling Solution

A drywall drop ceiling (or a drywall soffit) is a secondary ceiling built below the main structural ceiling. Unlike traditional suspended ceilings with visible tiles, a drywall drop ceiling provides a seamless, smooth finish.

It’s commonly used to:

- Conceal ductwork, pipes, and electrical conduits.

- Install recessed lighting.

- Create a dramatic ceiling design with multiple levels.

- Improve acoustics in a room.

The construction of a drywall drop ceiling is similar to that of a drywall partition, using a metal frame and drywall sheets to create the desired form.

Drywall vs. Sheetrock vs. Plaster: Clearing the Confusion

- Drywall: This is the generic term for the product category.

- Sheetrock: This is a registered trademark of the USG Corporation. It’s a brand of drywall, much like Kleenex is a brand of tissues. So, all Sheetrock is drywall, but not all drywall is Sheetrock. Sheetrock construction is simply a branded way of saying drywall construction.

- Drywall Plaster: This term can be confusing. It typically refers to the joint compound (“mud”) used to finish the drywall, not the wet plaster used in traditional lath and plaster walls. The drywall panel itself is sometimes called “pre-plastered board” because it creates a plaster-like surface without the mess.

Who Should Use a Drywall Partition and Where?

- Who? Almost anyone involved in building or renovating a space!

- Homeowners looking to create a new room, home office, or divide a large area.

- Contractors and Builders for fast and efficient construction of interior walls in new developments.

- Commercial Interior Designers for creating flexible office layouts, conference rooms, and retail spaces.

- Where?Drywall partitions are ideal for:

- Offices: Creating cubicles, private offices, and meeting rooms.

- Homes: Building new rooms, enclosing a loft, or creating a walk-in closet.

- Retail Stores: Partitioning stockrooms from the sales floor.

- Hotels: Constructing guest room walls.

Just as a well-planned Bar Bending Schedule (BBS) is crucial for reinforced concrete work, having a precise plan for your drywall partition ensures material efficiency and a perfect fit. And when you’re designing the built-in storage for your new room, check out our collection of Best Almari Designs for Bedroom DWG File Download for modern ideas.

Conclusion: Embrace the Flexibility of Drywall Partitions

The drywall partition is a testament to innovation in the construction industry. It offers a winning combination of speed, cost savings, flexibility, and performance that traditional methods struggle to match. Whether you’re a DIY enthusiast tackling a home project or a professional managing a large commercial fit-out, understanding the drywall meaning, its types, and its construction process is invaluable.

From the basic gypsum partition wall to more complex systems like a drywall drop ceiling, this versatile material allows you to shape your space exactly how you envision it. By being aware of potential issues like drywall tape bubbles and knowing how to address them, you can ensure your walls remain beautiful and durable for years to come.

For any construction project, accurate planning is key. Tools like our Free Building Estimation Excel Sheet and software like Microsoft Excel are indispensable for professionals looking to streamline their work, just as drywall is indispensable for modern interior construction.

Frequently Asked Questions (FAQs)

Q1: What is the actual drywall meaning?

A: Drywall is a building material used for creating interior walls and ceilings. It consists of a core of gypsum plaster sandwiched between two thick sheets of paper. The name comes from the fact that it replaces traditional wet plaster systems with a “dry” panel.

Q2: How is a drywall partition different from a brick wall?

A: A drywall partition is lighter, faster to build, and easier to modify or repair than a brick wall. Brick walls are load-bearing, stronger, and offer better thermal mass, but they are more expensive and time-consuming to construct.

Q3: What causes drywall tape bubbles and how can I prevent them?

A: Drywall tape bubbles are usually caused by insufficient joint compound under the tape, trapping air, or applying tape to a dirty or damp surface. To prevent them, ensure you apply a good bed of mud, firmly embed the tape, and smooth it out to remove all air pockets.

Q4: Can I use any screws for drywall installation?

A: No, you should always use proper drywall screws. These are designed to bite into the studs and countersink to the perfect depth without breaking the paper face of the drywall. Using wood screws or other types can lead to poor holding power and surface defects.

Q5: What are the main types of drywall for a bathroom?

A: For bathrooms and other high-moisture areas, you should use Moisture-Resistant or Mold-Resistant drywall (often identified by its green or blue paper facing). This type is specially formulated to withstand humidity and prevent mold growth.

External Resources for Further Reading:

- Gypsum Association: Using Gypsum Board – A great resource for technical details and standards related to gypsum-based products.

- This Old House: How to Hang Drywall – A visual and practical guide to the drywall installation process.

Hi! I’m Sandip, a civil engineer who loves sharing about Civil Engineering & new ideas and tips. My blog helps you learn about engineering in a fun and easy way!