Table of Contents

Core Cutting in Construction

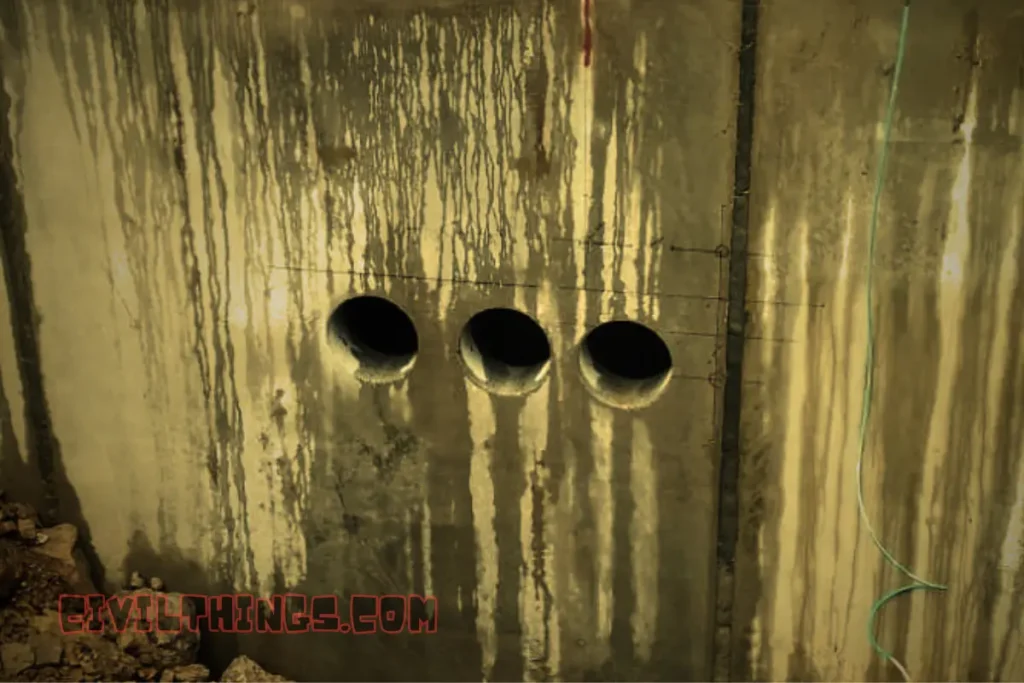

Precision drilling for openings in concrete structures

What is Core Cutting?

Core cutting is a specialized drilling process used in construction to create precise circular openings in concrete walls, floors, and ceilings for:

Purpose

- HVAC duct installations

- Plumbing pipes

- Electrical conduits

- Structural testing

- Creating openings for doors/windows

Benefits

- Precise, clean cuts

- Minimal vibration and noise

- No structural damage

- Dust-controlled operation

- Time-efficient process

The Core Cutting Process

Planning & Marking

Identify the exact location and mark the area for cutting after checking for embedded utilities.

Equipment Setup

Secure the core drill machine with anchor bolts or vacuum base to prevent movement during operation.

Water Supply Connection

Connect water supply to the drill for cooling and dust suppression (dry cutting is also possible).

Drilling Operation

Begin drilling at slow speed, gradually increasing as the bit penetrates the surface.

Core Removal

Extract the cylindrical concrete core once drilling is complete.

Cleanup

Remove debris and clean the area, ensuring a smooth finish.

Equipment Used

Core Drill Machine

Electric, hydraulic, or pneumatic powered drilling machine

Diamond Core Bits

Various diameters (1″-60″) with diamond segments for cutting

Anchor Bolts

For securing the drill to the surface

Water Supply System

For wet cutting operations

Vacuum Base

Alternative mounting system for core drills

Safety Gear

PPE for operators

Safety Considerations

- Always wear PPE: Safety glasses, ear protection, gloves, and respirator

- Check for utilities: Use scanners to detect rebar, post-tension cables, or embedded pipes

- Secure the machine: Proper anchoring prevents dangerous movement

- Monitor drill bit: Watch for signs of wear or overheating

- Control dust: Use water suppression or vacuum systems

- Follow manufacturer guidelines: For both equipment operation and maintenance

- Proper training: Only trained operators should perform core cutting

Applications in Construction

Structural

- Creating openings for elevators

- Staircase penetrations

- Ventilation shafts

- Utility chases

MEP Installations

- HVAC ductwork

- Plumbing pipes

- Electrical conduits

- Fire protection systems

Testing

- Concrete strength tests

- Material sampling

- Structural analysis

Renovation

- Retrofit installations

- Window/door openings

- Building modifications

Core cutting is a specialized drilling technique used to make circular holes through hard materials like concrete, brick, or stone. It is commonly used in construction for electrical conduits, plumbing lines, HVAC installations, and especially for air conditioner units.

In this detailed blog post, we will cover everything you need to know about core cutting, including core cutting machines, drill bits, bit sizes, and core cutting charges for split AC installation. Whether you’re a civil engineer, a contractor, or a homeowner, this guide will answer all your questions.

What is Core Cutting?

Core cutting is the process of drilling a clean, circular hole in a concrete or masonry surface. This method is efficient, less noisy, and produces minimal dust compared to traditional breaking methods. It is performed using a core cutting machine fitted with a suitable core cutting bit.

Applications of Core Cutting

Core cutting is widely used in both residential and commercial settings:

- Electrical conduit and switchboard installations

- Plumbing lines and pipe penetrations

- HVAC ducting and split AC pipe routes

- Firefighting lines and utility retrofits

- Concrete testing and sample extraction

- Borehole drilling for structural analysis

Using the right core cutting drill machine ensures accuracy, safety, and minimal disruption.

Concrete Core Cutting Machine

A concrete core cutting machine is a robust tool designed to cut through reinforced concrete surfaces like columns, beams, and slabs. These machines can be either hand-held for smaller jobs or mounted on stands for deeper or larger diameter holes.

Benefits:

- Precision drilling with minimal cracks

- Supports large diameter holes

- Efficient for heavy-duty concrete surfaces

Hilti Core Cutting Machine

Hilti is a renowned brand in the power tool industry. A Hilti core cutting machine is known for durability, precision, and reliability, making it the top choice for professionals.

Why Choose Hilti?

- Engineered for maximum safety

- Ideal for both dry and wet core cutting

- Built-in overload protection

- Longer service life and low maintenance

Professionals who need daily use and optimal results often invest in a Hilti core cutting machine.

Core Cutting Drill Machine

A core cutting drill machine is used to rotate the core bit and drill through surfaces. These machines come in various models: electric, hydraulic, or pneumatic, depending on the work scale.

Key Features to Consider:

- RPM adjustment control

- Compatibility with different bit sizes

- Built-in water supply for wet cutting

- Vibration and noise control mechanisms

Choose the drill machine based on your project size, frequency of use, and surface material.

Core Cutting Bit and Core Cutting Bit Sizes

A core cutting bit is a cylindrical-shaped tool used for drilling into surfaces. It is fitted at the tip of the machine and spins at high speed to drill through concrete, brick, or stone.

Common Core Cutting Bit Sizes:

- 25 mm: Electrical conduit pipes

- 50 mm: Water supply lines

- 65–90 mm: Split AC pipe outlets

- 100–150 mm: Ventilation and duct holes

- 200 mm+: Large penetrations and bore samples

Selecting the correct core cutting bit size ensures a clean and accurate hole, preventing damage to the surrounding surface.

Core Cutting for AC Installation

Split AC installations often require holes through RCC walls or thick brick masonry to route refrigerant pipes and drain lines. Core cutting for AC ensures a neat and clean outlet without damaging the structure.

Benefits of Core Cutting for AC:

- Neat circular holes without breaking the wall

- Avoids vibration cracks and structural damage

- Faster installation time for AC technicians

Whether you’re installing a new split AC or relocating an old unit, core cutting is essential for a damage-free setup.

Core Cutting Charges for Split AC

The core cutting charges for AC installation depend on several factors:

- Wall type (brick, block, or RCC)

- Hole diameter required

- Floor height (ground floor or high-rise)

- Accessibility to the area

Approximate Core Cutting Charges in Major Cities:

- Mumbai: ₹400 – ₹700

- Delhi: ₹350 – ₹650

- Bangalore: ₹500 – ₹800

- Pune: ₹400 – ₹650

- Hyderabad: ₹450 – ₹750

Some AC installation service providers include the cost in their overall quote, while others may charge separately for core cutting.

How to Choose the Right Core Cutting Drill Bit

Choosing the correct drill bit is vital for performance and safety:

- Material: Use diamond-coated bits for concrete and reinforced walls.

- Length: Depends on the wall thickness; use longer bits for deeper cuts.

- Diameter: Based on the pipe or duct size being inserted.

- Cooling: Use wet bits for large diameter or continuous drilling to avoid overheating.

Never use worn-out or low-quality bits, as they can damage the surface and the machine.

Safety Tips While Performing Core Cutting

Core cutting involves heavy-duty machinery and sharp tools, so safety is paramount.

- Wear safety goggles, ear protection, gloves, and a dust mask

- Always secure the core cutting machine properly before operation

- Use a wet cutting method to suppress dust and cool the bit

- Keep electrical cords away from water during wet drilling

- Never force the drill — let the bit cut at its own pace

- Disconnect power before changing bits

Professional operators are trained in these safety precautions to prevent workplace accidents.

FAQs

What is core cutting used for?

Core cutting is used to create circular holes in concrete or masonry walls for plumbing, electrical, HVAC, or other installations.

Is core cutting necessary for split AC installation?

Yes, core cutting is the best method for creating a clean, accurate hole in the wall for split AC pipes and drainage lines.

How much does core cutting cost?

Charges range from ₹350 to ₹800 depending on the wall type, city, and job difficulty.

Can I do core cutting myself?

If you have the right core cutting machine and safety gear, small jobs can be DIY. For concrete or load-bearing walls, professional help is recommended.

What’s the difference between a Hilti core cutting machine and a regular one?

Hilti machines offer better build quality, durability, and performance. They are ideal for regular and professional use, whereas generic machines suit light to medium tasks.

What is the lifespan of a core cutting bit?

A good-quality diamond core bit can last through dozens of cuts depending on the material, cooling system, and handling.

Conclusion

Core cutting plays an essential role in modern construction, renovations, and installations. From routing cables to installing a split AC, the process ensures clean, precise holes in concrete or masonry without damaging the structure.

Investing in the right core cutting drill machine, understanding core cutting bit sizes, and knowing core cutting charges can help homeowners and contractors make informed decisions. Whether you’re using a concrete core cutting machine or a premium Hilti core cutting machine, always prioritize safety and accuracy.

Also Read:

- Bar Bending Schedule (BBS): Step-by-Step Guide + Download BBS Excel Sheet Free

- Best Almari Designs for Bedroom DWG File Download (Free + Modern Ideas)

- How to Save Up to $5000 in Construction

- Row House Construction Estimation Excel Sheet

- STAAD Pro Software Free Download 2025

- Microsoft Excel Free Download for PC: The Ultimate Tool for Estimation and Costing in Civil Engineering

- ETABS Software Free Download for Windows 10

- Revit Software for Civil Engineering Download

Hi! I’m Sandip, a civil engineer who loves sharing about Civil Engineering & new ideas and tips. My blog helps you learn about engineering in a fun and easy way!