Table of Contents

Water cement Ratio Definition:

The water cement ratio refers to the ratio of the weight of water to the weight of cement used in concrete. A lower ratio typically results in higher strength and durability.

Importance of Water in Cement

- Micro Material Interaction: Concrete comprises various materials such as cement, sand, admixtures, and aggregates. Water plays a crucial role by facilitating chemical reactions with cement, forming bonds that fill the voids within the concrete, thereby preventing potential future cracks.

Factors Influencing Water Cement Ratio

- Exposure Conditions:

- Plain Cement Concrete (PCC)

- Reinforced Cement Concrete (RCC)

- Minimum Grade of Concrete:

- For PCC: Minimum Grade – M15

- For RCC: Minimum Grade – M20

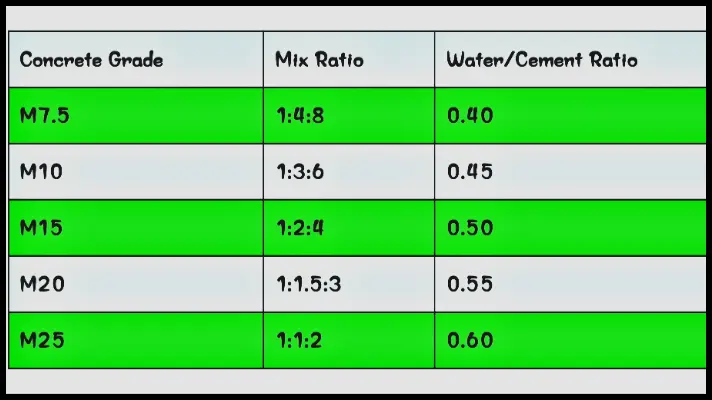

Water Cement Ratio Table

Tests for Determining Water Cement Ratio

- Vicat’s Apparatus (Consistency Test):

This test determines the consistency of cement paste by measuring the penetration of a plunger into the cement paste. It provides insights into the water requirement for achieving the desired consistency of concrete.

- Slump Cone Test (Workability Test):

The slump cone test evaluates the workability of concrete by measuring the consistency and flow of the concrete mix. It helps in assessing the appropriate water content necessary for the concrete to achieve the desired workability.

Additional Information

- Role of Consistency: The consistency of concrete affects its workability, strength, and durability. Achieving the right water cement ratio ensures optimal consistency, enhancing the overall quality of the concrete structure.

- Effect on Strength and Durability: A balanced water cement ratio is critical for ensuring the long-term strength and durability of concrete. Excessive water can weaken the concrete, while insufficient water may lead to inadequate hydration of cement particles, affecting its strength.

Calculation of Water Quantity for Concrete

For example, for RCC with M20 grade and a water cement ratio of 0.55, with each cement bag weighing 50kg:

Water Quantity = Cement Weight × Water Cement Ratio

= 50 kg × 0.55

= 27.5 kg

This calculation provides the amount of water required per bag of cement to achieve the desired water cement ratio.

FAQ RELATED TO WATER CEMENT RATIO

What is the water cement ratio, and why is it important in concrete construction?

The water cement ratio is the ratio of the weight of water to the weight of cement used in concrete. It is crucial because it directly affects the strength and durability of the concrete. A proper water cement ratio ensures optimal hydration of cement particles, leading to a strong and durable concrete structure.

How does the water cement ratio impact the strength and durability of concrete?

The water cement ratio significantly influences the strength and durability of concrete. An appropriate ratio ensures that the cement particles hydrate adequately, resulting in a dense and strong concrete matrix. Too much water can weaken the concrete by increasing porosity, while too little water can lead to incomplete hydration and reduced strength.

How is the water quantity for concrete calculated based on the water cement ratio?

The water quantity for concrete can be calculated using the formula:Water Quantity = Cement Weight × Water Cement RatioFor example, for RCC with M20 grade and a water cement ratio of 0.55, with each cement bag weighing 50kg:Water Quantity = 50 kg × 0.55 = 27.5 kgThis calculation provides the amount of water required per bag of cement to achieve the desired water cement ratio.

How can contractors ensure the proper water cement ratio in concrete construction?

Contractors should carefully proportion the ingredients of concrete, including cement, water, aggregates, and admixtures, to achieve the desired water cement ratio. They should also conduct tests such as the slump cone test and Vicat’s apparatus test to verify the consistency and workability of the concrete mix, adjusting the water content as needed to meet project requirements.

What are the commonly used tests to determine the water cement ratio?

Two commonly used tests are:Vicat’s Apparatus (Consistency Test): This test measures the penetration of a plunger into the cement paste to determine its consistency, aiding in assessing the water requirement for achieving the desired consistency of concrete.Slump Cone Test (Workability Test): This test evaluates the workability of concrete by measuring its consistency and flow. It helps determine the appropriate water content necessary for achieving the desired workability of concrete.

YouTube video related to water cement ratio

suggestions post related to concrete technology

Why Self Healing Concrete Used in Construction

17+ TYPES OF ADMIXTURE USED IN CONCRETE FOR EXAM 2024

Hi! I’m Sandip, a civil engineer who loves sharing about Civil Engineering & new ideas and tips. My blog helps you learn about engineering in a fun and easy way!

Comments are closed.