Engineered Cementitious Composite (ECC) Infographic

What is ECC?

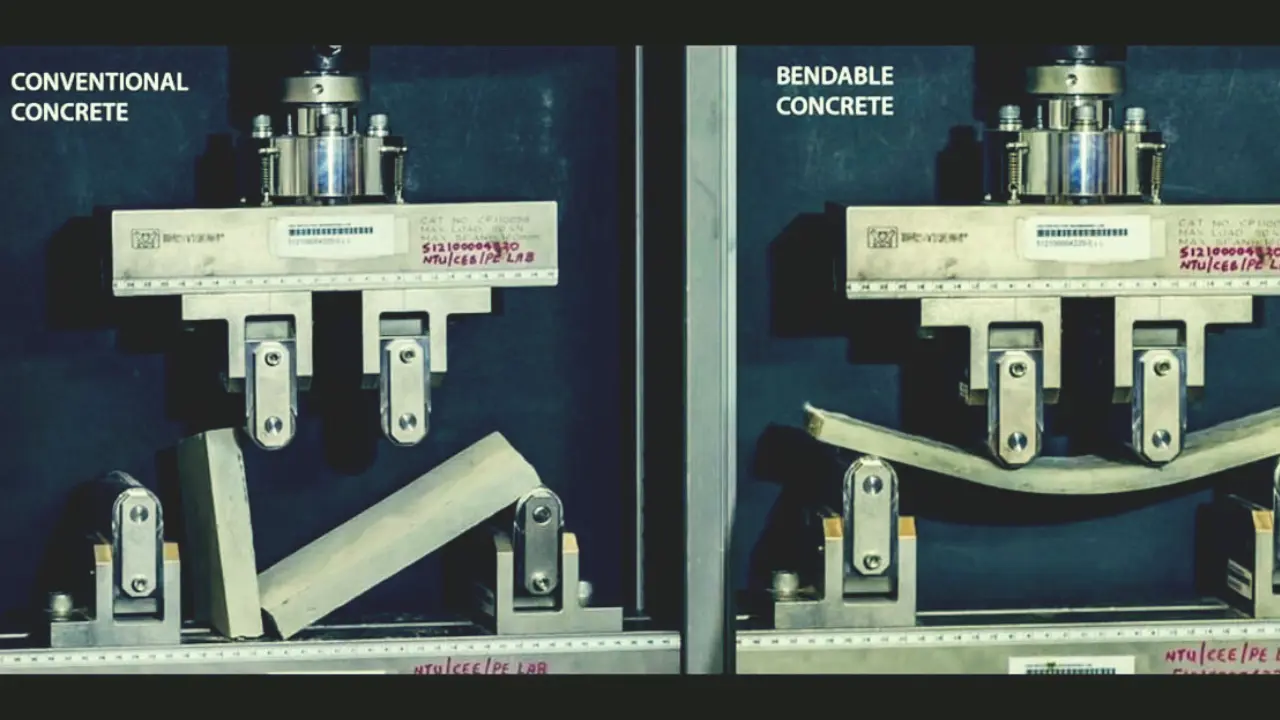

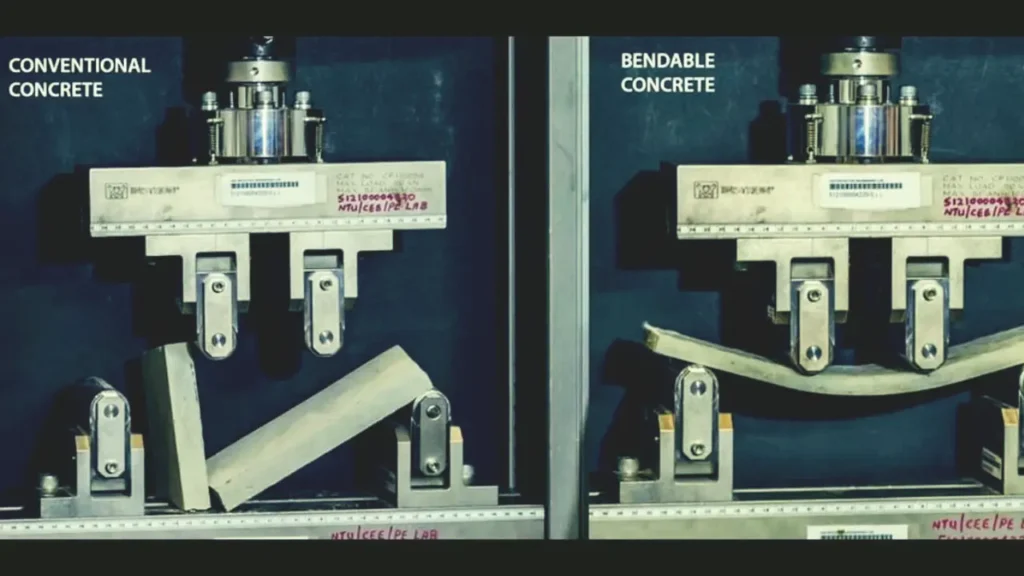

ECC, or Engineered Cementitious Composite, is a special type of concrete designed to be bendable and crack-resistant. It is made with fibers that give it enhanced strength and flexibility.

How to Make ECC (Materials & Ratio)

ECC is made using:

- Cement

- Fine Aggregates (like sand)

- Water

- Fibers (e.g., Polyvinyl Alcohol or Polyethylene)

- Admixtures (optional, for improved performance)

Typical mix ratio: 1 part cement : 0.8 parts fine aggregates : 0.5 parts water : 1.5-2% fibers by weight of cement.

Why Use ECC?

ECC offers:

- High ductility and flexibility

- Excellent crack resistance

- Durability and longevity

- Self-healing properties

Where is ECC Used?

Bridges

ECC is used to build bridges that need to withstand heavy loads and environmental stress.

Buildings

Used in earthquake-prone areas to enhance structural flexibility and safety.

Roads

Applied in pavements to reduce cracking and extend lifespan.

Repairs

Utilized for repairing old structures due to its durability and ease of use.

Engineered Cementitious Composite (ECC), also known as bendable concrete, is a special type of concrete that can bend without breaking. Unlike regular concrete, which cracks easily, ECC is very strong and flexible, making it perfect for building things that need to last a long time.

Key Points about ECC

- Bendable: ECC can bend and stretch without breaking, so it’s great for places that move a lot, like during an earthquake.

- Tiny Cracks: Instead of forming big cracks, ECC only gets tiny cracks, which helps keep it strong and safe.

- Fibers Inside: ECC has tiny fibers mixed in, which help make it even stronger and stop cracks from getting bigger.

- Self-Healing: Some types of ECC can fix their own small cracks when they get wet, almost like how our skin heals after a cut.

- Good for the Environment: Since ECC is so strong, we can use less of it, which is better for the planet.

Where ECC is Used

- Bridges: ECC is used in bridges to make them last longer without needing much repair.

- Earthquake-Resistant Buildings: Its flexibility makes ECC great for buildings in areas that have earthquakes.

- Roads: ECC is used in roads because it doesn’t crack easily, making roads last longer.

- Fixing Old Buildings: ECC is also used to repair old buildings, making them stronger and safer.

ECC is a super strong and bendable type of concrete that helps us build safer and longer-lasting structures.

ECC is a relatively new material, emerging from the laboratory to precast plants and construction sites. The material continues to evolve, and new characteristics are continually being uncovered. More and more applications are being found for ECC. There is a need to exchange evolving information among academic, industrial, and governmental entities. For this reason, the ECC Technology Network was established in 2001.

The ECC Technology Network is an informal organization composed of members interested in developing and promoting engineered cementitious composite technology. A website hosted by the University of Michigan at www.engineeredcomposites.com provides an international platform for sharing news and knowledge about ECC materials and application technologies. There is no cost to joining this organization, just a commitment to further advancing ECC.

V. C. Li / Journal of Advanced Concrete Technology Vol. 1, No. 3, 215-230, 2003

Hi! I’m Sandip, a civil engineer who loves sharing about Civil Engineering & new ideas and tips. My blog helps you learn about engineering in a fun and easy way!