Table of Contents

Culverts are one of the most essential yet often overlooked structures in civil engineering. Whether in rural roads, highways, or drainage systems, they play a crucial role in ensuring smooth water flow and preventing road damage. This guide will explain what is the meaning of Culvert, types, purposes, design considerations, and applications in different countries like Australia, along with essential tools such as culvert design excel sheets and culvert design calculation methods.

1. Introduction to Culverts

Before diving into technical details, let’s start with what is the meaning of Culvert.

A culvert is a structure that allows water to flow under a road, railway, or similar obstruction. It can be made from materials like concrete, steel, plastic, or stone. Essentially, it acts as a tunnel that channels water from one side to another, preventing flooding and erosion.

In civil engineering, culverts are vital for maintaining roadway stability and safety, especially in areas prone to heavy rains and waterlogging.

2. What is the Purpose of a Culvert?

If you’re wondering what is the purpose of culvert, the answer is straightforward — to provide a pathway for water flow without obstructing transportation routes.

Some key purposes include:

- Preventing water accumulation on roads

- Protecting road foundations from erosion

- Managing stormwater efficiently

- Providing safe crossing for small wildlife

- Supporting irrigation channels

3. Which is Used to Culvert?

When we discuss which is used to Culvert, we refer to the materials and designs that make culverts functional. Common materials include:

- Concrete – Durable and widely used for large-scale projects

- Steel – Ideal for high-load capacity

- Plastic (PVC/HDPE) – Lightweight and corrosion-resistant

- Stone masonry – Used in older or rural infrastructure

The choice depends on budget, design requirements, load capacity, and environmental conditions.

4. Types of Culverts

Culverts are classified based on shape, material, and construction method. Common types include:

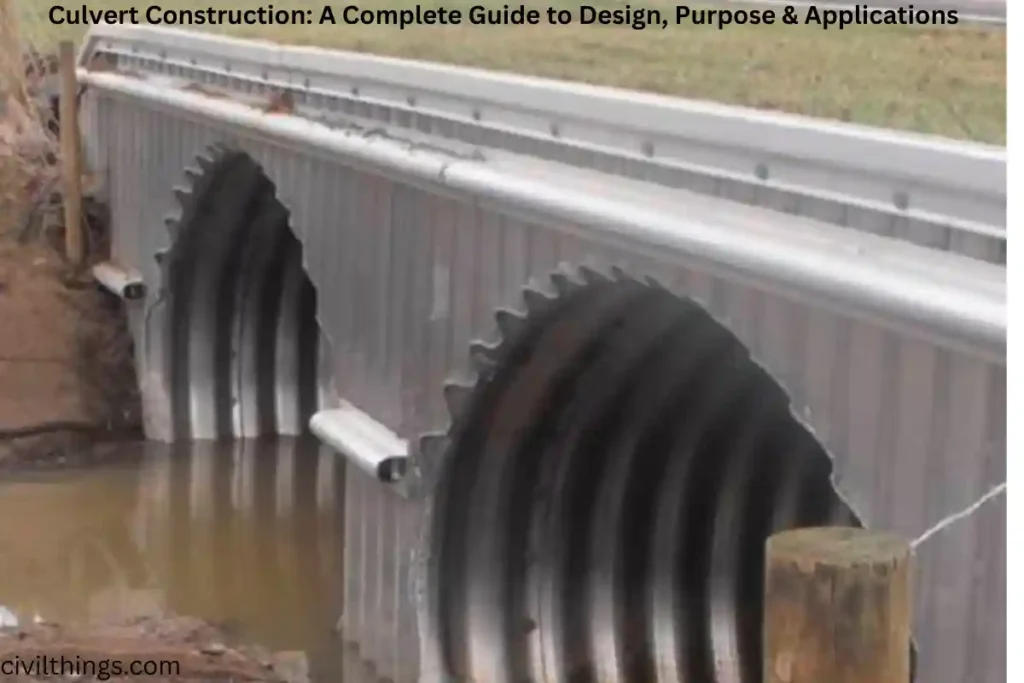

- Pipe Culvert – The most common type; circular in shape and made from concrete, steel, or plastic.

- Box Culvert – Rectangular or square, ideal for high-flow areas.

- Arch Culvert – Semi-circular design, aesthetically pleasing.

- Bridge Culvert – Combines a culvert with a bridge deck, suitable for both vehicular traffic and water flow.

- Pipe Arch Culvert – Modified pipe culvert with an arch design for better flow.

5. What is a Culvert in Australia?

In Australia, what is a culvert in Australia refers to a waterway passage that supports flood control and wildlife movement. Australian standards ensure culverts are designed to withstand extreme rainfall events and maintain ecological balance.

The Australian culvert standards focus on:

- Flood mitigation

- Fish passage requirements

- Durability against extreme weather

- Compliance with Austroads and Australian Standard AS 1597

6. Culvert Pipe: An Essential Component

The Culvert pipe is the central water-carrying unit of the culvert structure. They can be:

- Circular concrete pipes – Most common in urban drainage

- Corrugated metal pipes – Flexible and lightweight

- PVC/HDPE pipes – Cost-effective and resistant to chemical corrosion

Culvert pipes are installed at a slope to ensure smooth water discharge and reduce blockages.

7. What is Culvert Design?

When discussing what is culvert design, it refers to the process of planning a culvert’s size, shape, slope, and material to meet site-specific requirements.

A well-planned Culvert design considers:

- Hydraulic capacity (volume of water to pass)

- Structural load-bearing capacity

- Soil type and stability

- Environmental regulations

- Maintenance requirements

8. Culvert Design Calculation

Culvert design calculation is a critical step for engineers to determine the culvert’s dimensions, slope, and flow capacity. Factors include:

- Hydrological data – Rainfall intensity, catchment area

- Hydraulic formulas – Manning’s equation for flow rate

- Load analysis – Vehicle loads and soil pressure

- Safety factors – To prevent overflow and collapse

Example calculation parameters:

- Discharge capacity (Q) in cubic meters per second

- Pipe diameter (D) based on flow requirement

- Inlet and outlet velocity considerations

9. Using Culvert Design Excel Sheets

Modern engineers use culvert design excel sheets for quick and accurate calculations. These spreadsheets automate:

- Flow rate determination

- Pipe sizing

- Hydraulic gradient analysis

- Material estimation

Benefits:

- Saves time

- Reduces manual errors

- Allows easy design modifications

10. Culvert Bridge

A culvert bridge is a combination of culvert and bridge design, where the culvert provides water passage and the bridge deck supports road or rail traffic. These are common in rural areas and small river crossings.

Advantages:

- Cost-effective compared to full bridges

- Dual functionality for transportation and drainage

- Lower maintenance costs

11. Maintenance of Culverts

Culverts require periodic maintenance to prevent blockages and damage. This includes:

- Removing debris and sediment buildup

- Checking for cracks or joint separation

- Ensuring inlet and outlet clearance

- Recoating or repairing corroded metal parts

12. Challenges in Culvert Construction

Some challenges faced during culvert construction include:

- Incorrect hydraulic design leading to overflow

- Soil erosion around culvert ends

- Material degradation over time

- Wildlife obstruction if not designed properly

13. Innovations in Culvert Design

Modern Culvert design includes smart monitoring systems and eco-friendly construction materials. For example:

- Precast concrete culverts for faster installation

- Eco-passages for wildlife

- Sensor-based flow monitoring to prevent flooding

14. Summary Table: Culvert Types and Uses

| Type of Culvert | Material Used | Best For | Lifespan |

|---|---|---|---|

| Pipe Culvert | Concrete/Steel | Urban drainage | 50+ years |

| Box Culvert | Reinforced Concrete | High flow areas | 75+ years |

| Arch Culvert | Concrete/Stone | Aesthetic areas | 50+ years |

| Culvert Bridge | Concrete/Steel | Rural crossings | 60+ years |

| Pipe Arch Culvert | Corrugated Steel | Medium flow areas | 40+ years |

Conclusion

Culverts are more than just water channels under roads — they are vital infrastructure elements ensuring safe transportation and effective water management. Understanding what is the meaning of Culvert, what is culvert design, and the importance of culvert design calculation helps engineers create durable and efficient drainage solutions. From culvert pipe selection to advanced tools like culvert design excel, the right choices can make a significant difference in performance and lifespan.

Whether it’s a rural culvert bridge or an urban stormwater system, a well-designed culvert safeguards infrastructure, supports environmental sustainability, and ensures public safety.

Hello! I’m Vaishnavi, a civil engineer who enjoys sharing how we design and build structures. My blog makes understanding engineering easy and interesting for everyone!

1 thought on “Culvert Construction: A Complete Guide to Design, Purpose & Applications”

Comments are closed.